Table of Contents

Introduction

In the diverse and demanding landscape of Indian architecture, the definition of durability is constantly evolving. For decades, Indian homeowners relied on timber, accepting natural warping and cracking as unavoidable. As engineering evolves, so do expectations—doors must now withstand extreme environmental stress without losing form or function.

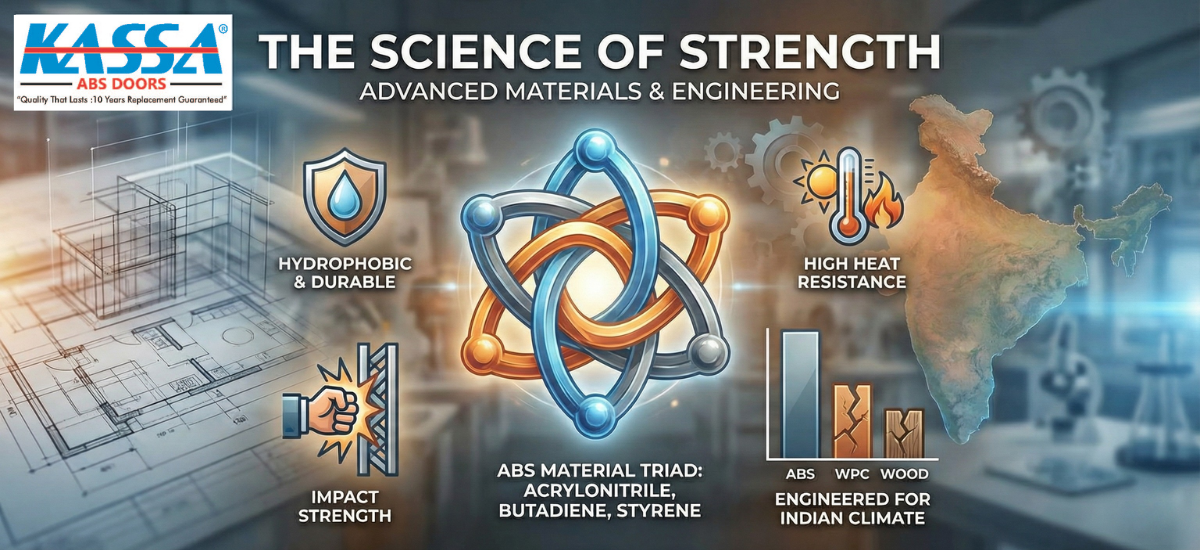

This shift has led to the rise of strong doors India trusts for long-lasting stability: ABS (Acrylonitrile Butadiene Styrene) doors.

At Kassa ABS Doors, we believe strength is not defined by weight but by molecular engineering. While wood and WPC have served India for decades, ABS represents the next generation of high-performance doors built for Indian climates.

This analysis breaks down the science behind ABS, the molecular triad that powers it, and the engineering choices that make Kassa ABS doors outperform traditional materials.

The Molecular Triad: What is ABS?

ABS is an engineering-grade thermoplastic terpolymer, created by polymerizing styrene and acrylonitrile in the presence of polybutadiene.

The “Triad of Strength” includes three :

1. Acrylonitrile: The Rigid Shield

Acrylonitrile provides:

- Rigidity

- Chemical resistance

- Structural stability

It ensures Kassa doors do not react to household chemicals and retain their shape for decades.

2. Butadiene: The Shock Absorber

Derived from natural rubber, Butadiene adds:

- Impact strength

- Flexural toughness

Daily slams, bumps, and rough handling are absorbed rather than causing cracks—making these some of the strongest doors India uses in high-traffic homes.

3. Styrene: The Aesthetic Finish

Styrene enables:

- Smooth surface

- Premium glossy finish

- Wood-grain textures through molding

This is what allows Kassa doors to look like premium timber while performing like an engineered polymer.

Debunking the “Hollow” Myth: Structural Engineering

The Honeycomb Core and Tubular Reinforcement

Kassa doors use:

- Honeycomb core (aerospace-style strength-to-weight ratio)

- Excellent sound insulation

- Anti-vibration stability

Laminated Veneer Lumber (LVL) Framework

The internal skeleton includes:

- LVL reinforcement

- Oxidized PVC bars

This ensures the door never bends, warps, or loses alignment. Unlike cheap PVC doors, a Kassa ABS door is a multi-layered composite system, not a hollow sheet.

Battling the Indian Sun: The Science of Heat Resistance

Heat is a major threat to traditional doors. PVC and low-grade WPC soften under high temperatures.

ABS, however, offers high thermal stability.

Withstanding 90°C to 120°C

- Direct heat: stable up to 90°C

- Indirect heat: stable up to 120°C

Why it matters:

- Balcony-facing doors

- Rooms with strong sunlight

- Indian summers reaching 45°C+

Kassa ABS doors maintain perfect alignment even in extreme heat.

The Moisture Menace: Hydrophobic vs. Hygroscopic

Wood and WPC (containing wood flour) are hygroscopic—they absorb moisture, leading to swelling and decomposition.

ABS is hydrophobic—it repels water naturally.

Moisture Benefits:

- No swelling

- No rot

- No fungus

- 100% waterproof surface

You can wash ABS doors with water without any dimensional change.

ABS vs. WPC: A Technical Comparison

Performance Table

| Feature | Kassa ABS Door | Standard WPC Door | Wooden Door |

|---|---|---|---|

| Surface Hardness | High (Impact Resistant) | Medium | High (but brittle) |

| Screw Holding Capacity | Excellent | Poor–Medium | Good |

| Heat Resistance | Up to 90°C direct | Low | High |

| Water Absorption | 0% (Hydrophobic) | Low (edges swell) | High |

| Weight | Optimized | Heavy | Heavy |

| Finish Technology | Vacuum Bonded | Painted / Laminate | Polished |

WPC’s weight strains hinges. ABS offers a superior strength-to-weight ratio, making it more durable.

Aesthetics Meets Engineering

ABS allows advanced thermal vacuum forming technology, bonding decorative sheets without glue. This ensures:

- No peeling

- Long-lasting finish

- Wood-like textures (Teak, Oak, Walnut)

- Scratch-resistant surfaces

ABS delivers beauty + durability.

Installation and Screw Holding Capacity

Kassa ensures strong installation through:

- PVC foam reinforcement bars

- LVL skeleton

This creates dense anchor points, eliminating screw loosening—a common problem with PVC and low-grade WPC.

Security: More Than Just a Barrier

Polybutadiene impact resistance makes Kassa doors:

- Difficult to break using blunt force

- Far stronger than hollow-core doors

- Suitable for both interior and semi-security applications

ABS doors enhance overall home safety.

The Eco-Friendly Perspective

ABS contributes to sustainability through:

Longevity

A product that lasts longer reduces waste.

Forest Conservation

ABS reduces demand for timber-based doors.

Recyclability

ABS is a thermoplastic—it can be recycled and repurposed.

Conclusion: The Smart Choice for Indian Homes

The shift to ABS is a technological evolution, not a trend.

The triad of Acrylonitrile, Butadiene, and Styrene creates a material that is:

- Mechanically stronger

- Thermally stable

- Chemically resistant

Combined with honeycomb cores and LVL reinforcement, Kassa ABS doors solve India’s biggest climate challenges—heat, humidity, and impact.

Kassa offers strong doors India needs for long-term performance, beauty, and peace of mind.

Ready to transform your home with the science of strength? Explore our collection today at Kassa Doors.